Product Description

Silicon Carbide (SiC) wafers thiab substrates yog cov khoom siv tshwj xeeb siv hauv semiconductor thev naus laus zis ua los ntawm silicon carbide, ib qho chaw paub txog nws cov thermal conductivity, zoo heev mechanical zog, thiab dav bandgap. Tshwj xeeb tshaj yog nyuaj thiab hnav, SiC wafers thiab substrates muab lub hauv paus ruaj khov rau fabricating high-power, high-frequency electronics, xws li lub hwj chim electronics thiab xov tooj cua zaus Cheebtsam.

Silicon carbide wafers 'cov khoom tshwj xeeb ua rau lawv zoo tagnrho rau cov ntawv thov uas yuav tsum tau ua haujlwm kub, hnyav ib puag ncig, thiab txhim kho lub zog ua haujlwm.

Piv nrog rau cov khoom siv Si cov pa, SiC-raws li cov khoom siv hluav taws xob muaj kev hloov pauv sai dua, muaj zog dua, qis dua cov kab mob sib kis, qhov ntau thiab tsawg, thiab cov cua txias tsawg dua vim qhov muaj peev xwm kub.

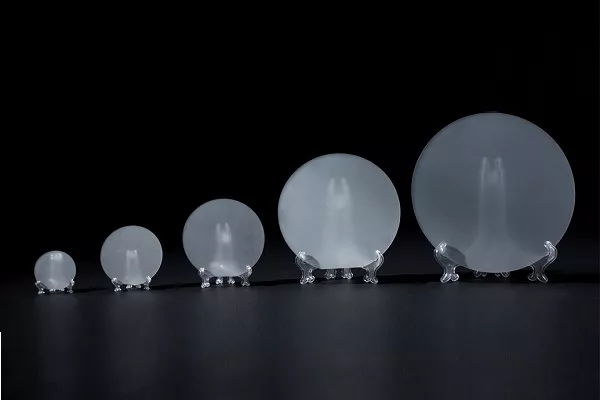

Peb cov silicon carbide wafers muaj nyob rau hauv ntau qhov ntau thiab tsawg thiab specifications, cia peb cov neeg muas zaub xaiv qhov zoo tshaj plaws kev xaiv rau lawv cov kev xav tau tshwj xeeb. Peb muab ob qho tib si liab qab wafers thiab epitaxial wafers, thiab peb tuaj yeem kho peb cov khoom kom tau raws li qhov yuav tsum tau ua ntawm txhua qhov haujlwm.

Ntawm SiBranch, peb tau cog lus los muab peb cov neeg siv khoom siab tshaj plaws ntawm kev pabcuam thiab kev txhawb nqa. Peb pab pawg kws tshaj lij yeej ib txwm muaj los teb cov lus nug thiab muab kev taw qhia txog cov khoom lag luam zoo tshaj plaws thiab cov kev daws teeb meem rau koj qhov project. SiBranch muab ntau yam khoom thiab kev pabcuam kom tau raws li cov kev xav tau ntawm peb cov neeg siv khoom. Tiv tauj peb hnub no kom paub ntau ntxiv txog peb cov khoom thiab peb tuaj yeem pab koj ua tiav koj lub hom phiaj.

|

4H N-HOM SiC 100MM, 350μm WAFER SPECIFICATION |

|||

|

Artic le Number |

W4H100N-4-PO (or CO)-350 |

||

|

Kev piav qhia |

4H SiC Substrate |

||

|

Polytype |

4H |

||

|

Txoj kab uas hla |

(100+00-0.5) hli |

||

|

Thickness |

(350 ± 25) μm (qib Engineering ± 50μm) |

||

|

Carrier Hom |

n-type |

||

|

Dopant |

Nitrogen |

||

|

Kev tiv thaiv (RT) |

0.012-0.025Ω▪cm (Qib Engineering<0.025Ω▪cm) |

||

|

Wafer Orientation |

(4+0.5) degree |

||

|

Qib Engineering |

Qib ntau lawm |

Qib ntau lawm |

|

|

2.1 |

2.2 |

2.3 |

|

|

Micropipe ntom ntom |

Tsawg dua los yog sib npaug li 30cm-² |

Tsawg dua los yog sib npaug li 10cm-² |

Tsawg dua los yog sib npaug li 1cm-² |

|

Micropipe Dawb cheeb tsam |

Tsis tau teev tseg |

Ntau dua lossis sib npaug li 96% |

Ntau dua lossis sib npaug li 96% |

|

Orientation tiaj tus (OF) |

|

||

|

Kev taw qhia |

Paralle {1-100} ± 5 degree |

||

|

Orientation tiaj tus ntev |

(32.5 ± 2. 0) mm |

||

|

Ldentification tiaj tus (IF) |

|

||

|

Kev taw qhia |

Si-face: 90 degree cw, los ntawm orientation ca ± 5 degree |

||

|

ldentification tiaj tus ntev |

(18.0+2 0) mm

|

||

|

Nto |

Option1: Si-face standard polish Epi-npaj C-face optical polish |

||

|

Option2: Si-face CMP Epi-npaj, C-face optical polish |

|||

|

Pob |

Ntau wafer (25) shipping thawv |

||

|

(Ib pob wafer raws li kev thov) |

|||

|

6H N-HOM SiC, 2 "WAFER SPECIFICATION |

|

|

Artic le Number |

W6H51N-0-PM-250-S |

|

Kev piav qhia |

Qhuav Qib 6H SiC Substrate |

|

Polytype |

6H |

|

Txoj kab uas hla |

(50.8 ± 38) hli |

|

Thickness |

250 ± 25 hli |

|

Carrier Hom |

n-type |

|

Dopant |

Nitrogen |

|

Kev tiv thaiv (RT) |

0 06-0.10Ω▪cm |

|

Wafer Orientation |

(0+0.5) degree |

|

Micropipe ntom ntom |

Tsawg dua los yog sib npaug li 100cm-² |

|

Orientation tiaj tus orientation |

Parallel {1-100} ± 5 degree |

|

Orientation tiaj tus ntev |

(15.88 ± 1.65) hli |

|

Kev qhia ncaj qha ncaj nraim |

Lub ntsej muag: 90 degree cw. Frow orientation tiaj tus ± 5 degree |

|

ldentification tiaj tus ntev |

(8+1.65) hli |

|

Nto |

Si-face standard polish Epi-npaj |

|

C-lub ntsej muag matted |

|

|

Pob |

Pob ib pob wafer lossis ntau lub thawv wafer shipping |

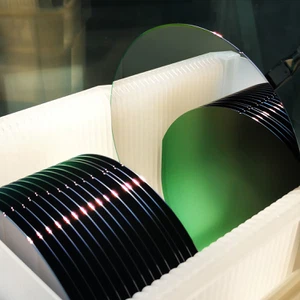

Khoom duab

Silicon Carbide (SiC) wafers yog ib hom khoom siv semiconductor siv los tsim cov khoom siv hluav taws xob thiab optoelectronic uas yuav tsum muaj qhov kub thiab txias, high-voltage, thiab kev ua haujlwm siab. SiC yog cov khoom siv dav-bandgap semiconductor, uas txhais tau hais tias nws muaj qhov tawg ntau dua thiab tuaj yeem ua haujlwm ntawm qhov kub siab dua li cov khoom siv semiconductors xws li silicon.

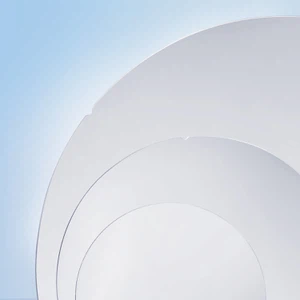

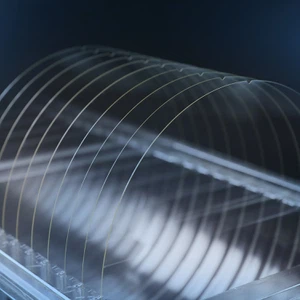

SiC wafers feem ntau yog tsim los ntawm kev siv lub cev vapor thauj (PVT) lossis tshuaj vapor deposition (CVD) txoj kev. Hauv PVT txoj kev, cov noob siv lead ua ntawm SiC tau muab tso rau hauv qhov cub kub kub thiab cov khoom siv, feem ntau silicon lossis carbon, yog cua sov kom txog thaum nws vaporizes. Cov vapor yog thauj los ntawm cov cab kuj roj, feem ntau argon, thiab tso rau ntawm cov noob siv lead ua, tsim ib txheej siv lead ua SiC. Hauv CVD txoj kev, SiC txheej yog tso rau ntawm lub substrate los ntawm reacting cov roj sib tov uas muaj silicon thiab carbon precursors ntawm qhov kub thiab txias.

Thaum SiC siv lead ua loj hlob tuaj, nws raug txiav rau hauv nyias wafers thiab polished mus rau qib siab ntawm flatness thiab smoothness. Qhov tshwm sim SiC wafers tuaj yeem siv los ua lub platform rau kev loj hlob ntawm cov txheej txheem semiconductor ntxiv, uas tuaj yeem doped nrog impurities los tsim p-hom thiab n-hom cheeb tsam rau kev tsim khoom.

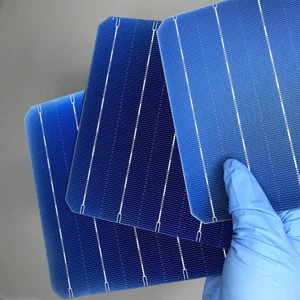

SiC wafers muaj ntau qhov zoo dua lwm cov khoom siv semiconductor xws li silicon. SiC muaj cov thermal conductivity ntau dua, uas txhais tau hais tias nws tuaj yeem ua haujlwm ntawm qhov kub siab dua yam tsis muaj kev cuam tshuam los ntawm thermal tawg. Tsis tas li ntawd, SiC muaj lub zog tawg ntau dua thiab tuaj yeem ua haujlwm ntawm cov hluav taws xob ntau dua thiab cov zaus ntau dua li silicon, ua rau nws tsim nyog rau kev siv xws li hluav taws xob hluav taws xob thiab cov khoom siv hluav taws xob siab.

Sib sib zog nqus khawb rau hauv SiC Wafers Properties

Cov qauv hluav taws xob tshwj xeeb ntawm SiC wafers yog tus yuam sij rau lawv cov khoom tshwj xeeb. Lub dav bandgap tsim ib qho teeb meem siab rau electrons kom kov yeej, ua rau ob qho txiaj ntsig tseem ceeb:

Kev kub ntxhov siab:Tsawg cov neeg nqa khoom nruab nrab qis txhais tau tias SiC cov cuab yeej tuaj yeem ua haujlwm ntawm qhov kub siab yam tsis muaj qhov cuam tshuam loj, zoo tagnrho rau qhov xav tau ib puag ncig.

High Breakdown Electric Field:Qhov dav bandgap kuj tseem ua rau muaj peev xwm tiv taus cov hluav taws xob siab, tso cai rau cov khoom siv nrog cov hluav taws xob thaiv hluav taws xob siab thiab qis hauv xeev tsis kam.

Tshaj li cov khoom hluav taws xob, SiC wafers ua tau zoo hauv thermal thiab mechanical yam zoo li.

Efficient Thaum tshav kub kub Dissipation:Qhov tshwj xeeb thermal conductivity tso cai rau SiC kom tshem tawm cov cua sov, qhov tseem ceeb rau kev siv hluav taws xob siab.

Durability hauv Harsh Environments:Lub zog txhua yam thiab hardness ua rau SiC resistant rau hnav thiab tsim kua muag, haum rau xav tau ib puag ncig.

SiC los ntawm ntau hom hu ua polytypes, txawv los ntawm stacking kev npaj ntawm silicon thiab carbon atoms. Ntawm cov no, 4H-SiC thiab 6H-SiC yog qhov tseem ceeb tshaj plaws hauv hluav taws xob.

4 H-SiC:Txaus siab rau cov hluav taws xob hluav taws xob vim nws cov khoom siv hluav taws xob zoo tshaj plaws thiab dav bandgap, txhais kom ua tau zoo dua thiab ua haujlwm tau zoo.

6 H-SiC:Pom cov ntawv thov nyob rau hauv qhov kub thiab txias thiab cov khoom siv ntau zaus vim nws qhov siab dua qhov kev txav mus los thiab me ntsis nqaim bandgap.

Kev xaiv ntawm polytype hinges ntawm daim ntawv thov tshwj xeeb cov kev xav tau. Cov yam ntxwv xws li cov khoom siv hluav taws xob xav tau, kev ua haujlwm, thiab kev ua haujlwm ntawm cov cuab yeej siv tau ua lub luag haujlwm hauv kev xaiv hom SiC wafer zoo.

Vim Li Cas Xaiv Peb

Peb cov khoom yog sourced tshwj xeeb los ntawm lub ntiaj teb no sab saum toj tsib manufacturers thiab ua domestic factories. Kev txhawb nqa los ntawm cov kws tshaj lij hauv tsev thiab thoob ntiaj teb cov kws tshaj lij pab pawg thiab kev tswj xyuas nruj.

Peb lub hom phiaj yog los muab cov neeg siv khoom nrog kev txhawb nqa ib leeg rau ib leeg, ua kom cov kev sib txuas lus zoo uas muaj kev tshaj lij, raws sijhawm, thiab ua haujlwm tau zoo. Peb muab qhov tsawg kawg nkaus txiav txim kom muaj nuj nqis thiab lav kev xa khoom sai hauv 24 teev.

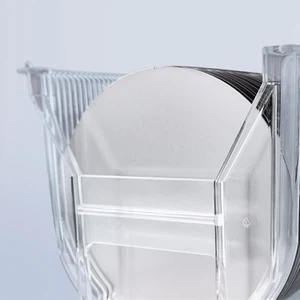

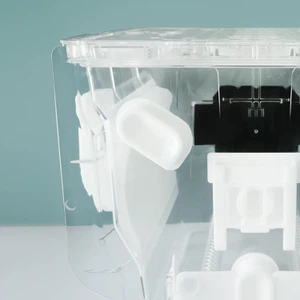

Factory Show

Peb cov khoom lag luam loj muaj 1000+ cov khoom, kom ntseeg tau tias cov neeg siv khoom tuaj yeem xaj kom tsawg li ib thooj. Peb tus kheej cov khoom siv rau dicing & backgrinding, thiab tag nrho kev koom tes nyob rau hauv lub ntiaj teb no kev lag luam saw pab kom peb sai li sai tau cov zaub mov xa tuaj kom ntseeg tau tias cov neeg siv khoom txaus siab thiab yooj yim.

Peb Daim Ntawv Pov Thawj

Peb lub tuam txhab txaus siab rau ntau daim ntawv pov thawj peb tau txais, suav nrog peb daim ntawv pov thawj patent, ISO9001 daim ntawv pov thawj, thiab daim ntawv pov thawj National High-Tech Enterprise. Cov ntawv pov thawj no sawv cev rau peb txoj kev mob siab rau kev tsim kho tshiab, kev tswj xyuas zoo, thiab kev cog lus rau kev ua tau zoo.

Cim npe nrov: Tuam Tshoj sic wafer manufacturers, lwm tus neeg, Hoobkas