Semiconductor Cheebtsam kev tsim khoom muaj cov txheej txheem ntau lawm los hloov cov ntaub ntawv raw rau hauv cov khoom tiav rau ntau yam kev siv uas muab kev tswj xyuas tseem ceeb thiab kev paub txog kev ua haujlwm.

Kev tsim khoom semiconductor suav nrog cov txheej txheem nyuaj los hloov cov ntaub ntawv raw rau hauv cov khoom tiav tiav. Cov txheej txheem tsim khoom semiconductor feem ntau suav nrog plaub theem tseem ceeb: wafer manufacturing, wafer xeem sib dhos lossis ntim, thiab kev sim zaum kawg. Txhua theem muaj nws cov kev sib tw tshwj xeeb thiab lub cib fim.

Cov txheej txheem tsim khoom semiconductor tseem ntsib ntau yam teeb meem nrog rau cov nqi, kev nyuaj, ntau haiv neeg thiab cov txiaj ntsig, tab sis kuj coj tau zoo rau kev tsim kho tshiab thiab kev loj hlob. Los ntawm kev hais daws cov teeb meem thiab txeeb cov hauv kev, peb tuaj yeem txhawb txoj kev loj hlob ntawm cov thev naus laus zis tshiab los hloov txoj kev peb nyob thiab ua haujlwm, thaum ua rau kev lag luam txuas ntxiv txhim kho thiab loj hlob.

Ib. Txheej txheem cej luam ntawm semiconductor manufacturing txheej txheem

Cov txheej txheem ntawm kev tsim khoom semiconductors tuaj yeem muab faib ua cov kauj ruam tseem ceeb hauv qab no.

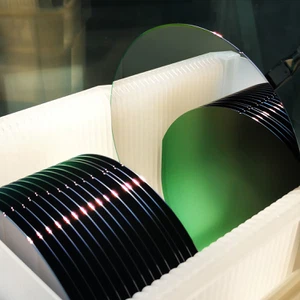

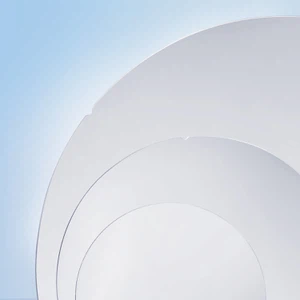

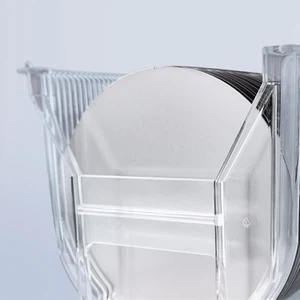

1. Kev npaj wafer

Silicon wafers raug xaiv los ua cov khoom pib rau cov txheej txheem semiconductor. Cov wafers raug ntxuav, polished, thiab npaj siv los ua cov substrates rau kev tsim khoom siv hluav taws xob.

2. Kev ua qauv

Hauv cov txheej txheem no, cov qauv tsim ntawm silicon wafers siv cov txheej txheem hu ua photolithography. Ib txheej ntawm corrosion-resistant photoresist yog siv rau saum npoo ntawm wafer, thiab tom qab ntawd ib daim npog qhov ncauj muab tso rau saum lub wafer. Lub npog ntsej muag muaj cov qauv sib xws rau cov khoom siv hluav taws xob ua ntej ua ntej. Cov qauv yog ces pauv los ntawm lub npog ntsej muag mus rau txheej txheej photoresist siv ultraviolet lub teeb. Tom qab ntawd cov cheeb tsam uas raug photoresist raug tshem tawm, tawm hauv qhov chaw ntawm lub wafer.

3. Khoom siv doping

Hauv cov kauj ruam no, cov ntaub ntawv tau ntxiv rau silicon wafer los hloov nws cov khoom hluav taws xob. Cov khoom siv feem ntau yog boron lossis phosphorus, uas tuaj yeem muab ntxiv rau hauv me me los tsim p-hom lossis n-hom semiconductors, feem. Cov ntaub ntawv no yog cog rau hauv qhov chaw ntawm lub wafer siv ion acceleration hauv cov txheej txheem hu ua ion implantation.

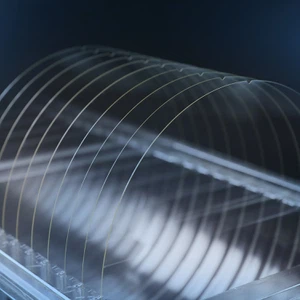

4. Wafer deposition processing

Thaum lub sijhawm txheej txheem no, cov ntaub ntawv nyias nyias tau muab tso rau ntawm wafer los tsim cov khoom siv hluav taws xob. Qhov no tuaj yeem ua tiav los ntawm ntau cov txheej txheem, suav nrog tshuaj vapor deposition (CVD), lub cev vapor deposition (PVD), thiab atomic txheej deposition (ALD). Cov txheej txheem no tuaj yeem siv los tso cov ntaub ntawv xws li hlau, oxides, thiab nitrides.

5. Etching

Tshem tawm ib feem ntawm cov khoom siv los ntawm qhov chaw ntawm wafer los tsim cov duab thiab cov qauv tsim nyog rau cov khoom siv hluav taws xob. Etching tuaj yeem ua tau siv ntau hom kev kawm, suav nrog ntub etching, qhuav etching, thiab plasma etching. Cov txheej txheem no siv cov tshuaj los yog cov ntshav plasma los xaiv cov khoom tshwj xeeb los ntawm cov wafer.

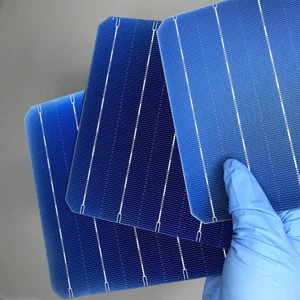

6. Ntim

Cov khoom siv hluav taws xob tau ntim rau hauv cov khoom kawg uas tuaj yeem siv rau hauv cov khoom siv hluav taws xob. Qhov no suav nrog kev txuas cov khoom sib txuas mus rau lub substrate xws li lub rooj tsav xwm luam tawm, thiab tom qab ntawd txuas lawv mus rau lwm cov khoom siv xov hlau lossis lwm yam. Cov txheej txheem semiconductor yog qhov nyuaj heev thiab koom nrog ntau yam khoom tshwj xeeb thiab cov khoom siv. Cov txheej txheem no yog qhov tseem ceeb rau kev tsim cov khoom siv hluav taws xob niaj hnub no thiab txuas ntxiv mus txuas ntxiv nrog kev hloov pauv ntawm cov thev naus laus zis tshiab.

Feem ntau, cov txheej txheem ntawm kev tsim cov semiconductor chips yuav siv li ob peb lub lis piam mus rau ob peb lub hlis. Pib los ntawm thawj theem, silicon wafer yuav tsum tau tsim los ua lub substrate rau cov nti. Cov txheej txheem no feem ntau suav nrog cov txheej txheem hauv qab no, tu, tso tawm, lithography, etching thiab doping. Lub wafer yuav xav tau ntau pua txoj haujlwm sib txawv, yog li tag nrho cov txheej txheem wafer yuav siv sijhawm txog 16-18 lub lis piam.

Thaum cov chips ib tus neeg raug tsim tawm ntawm lub wafer, lawv yuav tsum tau muab cais thiab ntim rau hauv ib qho chaw. Qhov no kuj suav nrog kev sim txhua lub nti kom ntseeg tau tias nws ua tau raws li cov lus qhia tshwj xeeb, thiab tom qab ntawd cais nws los ntawm wafer thiab txuas rau ntawm pob lossis substrate. Tom qab cov chips tau ntim, lawv yuav dhau los ntawm cov txheej txheem kev sim nruj kom ntseeg tau tias lawv ua tau raws li cov qauv zoo thiab ua tiav cov haujlwm xav tau. Qhov no suav nrog kev sim ua hluav taws xob, kev sim ua haujlwm, thiab lwm yam kev kuaj xyuas kom paub tseeb tias muaj teeb meem lossis teeb meem. Qhov no kuj yog nyob ntawm qhov nyuaj ntawm cov nti thiab cov kev xav tau ntawm kev sim, yog li cov txheej txheem ntim khoom thiab kev sim no tuaj yeem siv sijhawm 8-10 lub lis piam.

Tag nrho cov nyob rau hauv tag nrho, tag nrho cov txheej txheem ntawm kev tsim semiconductor chips yuav siv sij hawm ob peb lub lis piam los yog lub hlis, vim hais tias nws nyob ntawm seb cov technologies uas siv thiab cov complexity ntawm lub nti tsim.

2. Kev Nyuaj Siab thiab Kev Sib Tw hauv Semiconductor Manufacturing

1. Qauv Hloov

Kev nce qib hauv cov qauv hloov tshuab tau dhau los ua tus tsav tsheb tseem ceeb ntawm txoj kev loj hlob sai ntawm kev lag luam semiconductor, ua rau kev tsim khoom ntawm cov khoom siv hluav taws xob me thiab ntau dua.

Ib qho kev nce qib loj hauv cov qauv hloov tshuab yog kev txhim kho cov lithography siab, uas yog cov txheej txheem ntawm kev hloov cov qauv mus rau nruab nrab siv lub teeb lossis lwm qhov chaw hluav taws xob. Hauv particular, lithography technologies tsim nyob rau hauv xyoo tas los no, xws li huab ultraviolet (EUV) lithography thiab ntau yam qauv siv tshuab, yog siv los tsim cov duab me thiab ntau dua.

EUV lithography siv cov kab hluav taws xob luv luv ntawm lub teeb los tsim cov qauv zoo heev ntawm silicon wafers. Lub tshuab no tuaj yeem tsim qhov loj me me li ob peb nanometers, uas yog qhov tseem ceeb rau kev tsim cov khoom siv hluav taws xob zoo xws li microprocessors.

Ntau tus qauv yog lwm lub tshuab lithography uas tuaj yeem tsim cov qauv me me. Cov cuab yeej no suav nrog kev rhuav tshem ib qho qauv rau hauv ntau tus qauv micro-polar thiab tom qab ntawd hloov lawv mus rau saum npoo ntawm wafer. Yog li ntawd, cov qauv tsim tuaj yeem ua me dua li lub wavelength ntawm cov hluav taws xob siv hauv lithography.

2. Doping

Dopants yog qhov sib ntxiv ntawm cov xov xwm tshwj xeeb rau silicon wafers los hloov lawv cov khoom hluav taws xob. Kev nce qib hauv doping thev naus laus zis tau ua qhov tseem ceeb hauv kev txhim kho sai ntawm kev lag luam semiconductor. Qhov kev txhim kho thev naus laus zis no yog vim qhov tshwm sim ntawm cov khoom siv hluav taws xob tshiab.

Kev lig kev cai, boron thiab phosphorus yog cov khoom siv doping feem ntau vim tias lawv tuaj yeem tsim p-hom thiab n-hom semiconductors, feem. Txawm li cas los xij, nyob rau xyoo tas los no, cov ntaub ntawv tshiab xws li germanium, arsenic thiab antimony tau tsim thiab tuaj yeem siv los tsim cov khoom siv hluav taws xob ntau dua.

Lwm qhov kev nce qib hauv doping thev naus laus zis yog kev nce qib ntawm cov txheej txheem doping ntau dua. Yav dhau los, ion implantation yog cov thev naus laus zis tseem ceeb siv rau doping, nrog rau kev siv cov ions siab ceev los cog dielectrics rau saum npoo ntawm wafer. Txawm hais tias ion implantation tseem niaj hnub siv, cov thev naus laus zis tshiab xws li molecular beam epitaxy (MBE) thiab tshuaj vapor deposition (CVD) tau tsim los pab kom muaj kev tswj xyuas ntau dua ntawm cov txheej txheem doping.

3. Kev tso tawm

Deposition yog lwm txoj kev tseem ceeb hauv kev tsim khoom semiconductor, uas suav nrog kev tso cov yeeb yaj kiab nyias ntawm cov khoom mus rau hauv substrate. Cov txheej txheem no tuaj yeem ua tiav los ntawm ntau yam thev naus laus zis, xws li lub cev vapor deposition (PVD), tshuaj vapor deposition (CVD), atomic txheej deposition (ALD), thiab lwm yam.

Nyob rau tib lub sijhawm, cov thev naus laus zis tshiab kuj tseem txhim kho tas li, suav nrog hlau organic chemical vapor deposition (MOCVD), plasma enhanced deposition, yob-rau-yob deposition, thiab lwm yam.

4. Etching

Etching suav nrog tshem cov ntu tshwj xeeb ntawm cov khoom siv semiconductor los tsim cov qauv lossis cov qauv. Kev nce qib hauv etching thev naus laus zis yog qhov laj thawj tseem ceeb rau txoj kev loj hlob sai ntawm kev lag luam semiconductor thiab tseem yog cov cuab yeej tseem ceeb rau kev tsim cov khoom siv hluav taws xob me me thiab nyuaj dua.

Yav dhau los, ntub dej etching yog cov cuab yeej tseem ceeb uas feem ntau siv, uas cuam tshuam nrog cov wafer hauv cov tshuaj uas dissolves cov khoom. Txawm li cas los xij, kev ntub dej ntub dej tsis yog qhov tseeb thiab tuaj yeem ua rau muaj kev puas tsuaj rau cov qauv uas nyob ib sab.

Qhov tshwm sim ntawm qhuav etching thev naus laus zis tau ua kom muaj tseeb thiab tswj tau zoo heev, xws li reactive ion etching (RIE) thiab plasma etching. RIE yog ib qho kev siv tshuab uas siv cov ions reactive los xaiv tshem tawm cov khoom ntawm lub wafer, tso cai rau kev tswj cov txheej txheem etching.

Plasma etching yog cov cuab yeej zoo sib xws uas siv cov roj plasma tshem tawm cov khoom siv, tab sis nws muaj txiaj ntsig ntxiv ntawm kev xaiv tshem tawm cov khoom tshwj xeeb, xws li hlau lossis silicon.

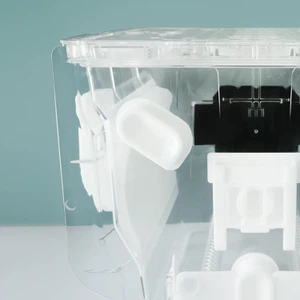

5. Ntim

Cov txheej txheem ntim hauv cov khoom siv hluav taws xob semiconductor suav nrog kev sib xyaw ua ke hauv ib qho kev tiv thaiv uas tseem muab kev sib txuas hluav taws xob rau lub ntiaj teb sab nraud. Cov txheej txheem ntim khoom cuam tshuam rau kev ua haujlwm, kev cia siab, thiab tus nqi ntawm cov khoom kawg.

3D ntim yuav tsum stacking ntau chips ua ke los tsim high-density integrated circuits. Cov thev naus laus zis no tuaj yeem txo qhov loj ntawm tag nrho cov cuab yeej thiab txhim kho nws cov kev ua tau zoo thaum tseem txo qis kev siv hluav taws xob.

Ntxuam-tawm ntim khoom yog ib qho kev siv tshuab uas embeds integrated circuits nyob rau hauv ib txheej ntawm epoxy molding compound, siv tooj liab ncej fanned tawm ntawm lub nti rau hluav taws xob sib txuas. Cov cuab yeej no ua rau cov ntim ntim siab hauv qhov me me.

System-in-Package (SiP) yog lwm lub thev naus laus zis uas ua ke nrog ntau lub chips, sensors, thiab lwm yam khoom siv rau hauv ib pob. Nws tuaj yeem txo qhov loj tag nrho ntawm cov cuab yeej thaum tseem txhim kho nws qhov kev ua tau zoo tag nrho.