Kev npaj ua ntej polishing

Ua ntej pib cov txheej txheem polishing tiag tiag, muaj ob peb yam tseem ceeb ntawm kev npaj:

Ntxuav

Ua tib zoo ntxuav qhov chaw wafer kom tshem tawm cov khoom seem lossis cov tshuaj lom neeg los ntawm cov txheej txheem ua ntej xws li lapping lossis etching. Kev sib kis tuaj yeem ua rau muaj qhov tsis xws luag thaum polishing. Peb pom zoo kom ntxuav ntawm:

SC -1 huv- Kub ammonium hydroxide, hydrogen peroxide, thiab dej hauv qhov sib piv ntawm 1: 1: 5 ntawm 75 degree rau 10 feeb

SC -2 huv- Kub hydrochloric acid, hydrogen peroxide, thiab dej hauv qhov sib piv ntawm 1: 1: 6 ntawm 75 degree rau 10 feeb

Quick pov tseg yaug (QDR)- Ntau da dej ntawm DI dej ntau dhau rau 2-3 feeb txhua

Kev tshuaj xyuas

Ua tib zoo tshuaj xyuas qhov chaw wafer tom qab ntxuav siv hom brightfield los xyuas:

Residual hais los yog stains

Pits, khawb, los yog subsurface puas los ntawm cov txheej txheem ua ntej

Lwm yam tsis xws luag xws li ntug chips / tawg

Hais txog tej teeb meem nyob rau theem no ua ntej polishing kom tsis txhob exacerbating defects.

Siv Backing Layer

Siv cov nplaum nplaum rov qab rau sab nraub qaum ntawm lub wafer los muab kev txhawb nqa zoo ib yam thaum polishing thiab tiv thaiv kev puas tsuaj rau sab nraub qaum:

Siv 1-2 txheej ntawm UV curable nplaum

Xyuas kom tag nrho kho ua ntej polishing

Table 1. Pom zoo cov txheej txheem rov qab

| Khoom siv | Hardness | Thickness | Kho Sijhawm |

|---|---|---|---|

| PU | Ntug A 60 | 0.5 hli | 5 feeb |

| Solgel | Ntug Dej D 20 | 0.2 hli | 10 sec |

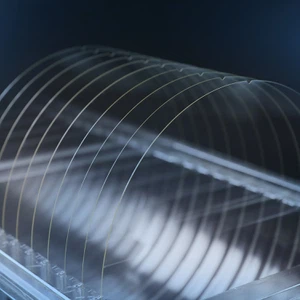

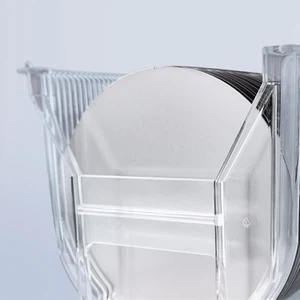

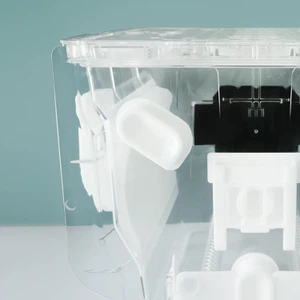

Cov khoom siv polishing

![]()

Muaj peev xwm tseem ceeb:

Hloov spindle ceev mus txog 120 rpm

Programmable downforce / siab txog li 8 psi

Real-time torque saib xyuas

Automated slurry dispensing / pub

Integrated post-polish tu chaw

Cov txheej txheem polishing

Cov kauj ruam tseem ceeb ntawm polishing tau piav qhia hauv qab no:

Npaj / Hnav Polishing Pad

Xaiv cov ntaub ntawv uas tsim nyog (saib cov lus pom zoo tom qab)

Kho cov ntaub qhwv tshiab los ntawm pob zeb diamond impregnating

Ua ntej txhua qhov kev khiav, hnav khaub ncaws nrog pob zeb diamond disc kom rov ua dua

Mount Wafer

Ruaj ntseg wafer khov kho rau wafer chuck/carrier

Center wafer kom zoo los xyuas kom meej polishing

Teem txheej txheem Parameter

Spindle ceev -30-60 rpmyam

Siab -3-5 psiyam

Slurry feed rate -100-250 ml/min

Lub sijhawm txheej txheem - nyob ntawm seb cov khoom yuav tsum tau tshem tawm

Pib Polishing Cycle

Pib spindle rotation

Dispense slurry mus rau qhov chaw ntawm lub ncoo tsis tu ncua

Qis wafer chuck thiab koom pad rau ib lub teeb siab

Saib xyuas torque thoob plaws hauv cov txheej txheem

Tom qab Polish Ntxuav

Kev tu kom huv tom qab polishing yog qhov tseem ceeb rau kev tshem tawm cov khoom seem thiab txo qhov tsis xws luag:

Lub hauv paus huv- Txhuam txhuam wafer nto nrog ammonium hydroxide lossis acetate raws li kev daws teeb meem

Secondary huv- Kev poob qis hauv HF lossis lwm cov kua qaub kom tshem tawm cov tshuaj seem

QDR - Ntau qhov dej ntau dhau rau 3-5 feeb txhua

Tshawb xyuas cov wafers tiav dua tom qab ntxuav. Rework/re-polish tej qhov chaw tsim nyog ua ntej mus rau cov txheej txheem tom ntej.

Silicon Wafer Polishing txheej txheem Optimization

Muaj ntau ntau qhov tseem ceeb uas tuaj yeem hloov kho kom zoo rau cov txheej txheem wafer polishing:

Applied Downforce/Pressure

Siab siab nce polishing / cov khoom tshem tawm tus nqi

Lub siab ntau dhau ua rau cov ntug sib npaug, microcracks

3-5 psi zoo rau feem ntau daim ntawv thov

Kev sib hloov ceev

Ua kom kub ntawm pad-wafer interface

Kev nrawm dua nce polishing tus nqi mus txog rau qhov taw tes

30-60 rpmhaum rau feem ntau cov txheej txheem batch

Cov ntaub ntawv Pad

Kev xaiv cov ntaub qhwv ntsej muaj feem cuam tshuam rau yam tseem ceeb xws li polishing tus nqi, nto tiav, thiab qib tsis xws luag:

Table 2. Cov ntaub ntawv sib piv

| Pad | Hardness | Kev tshem tawm tus nqi | Ua kom tiav | Tsis zoo | Nqi |

|---|---|---|---|---|---|

| Polyurethane | Nruab nrab | Nruab nrab | Zoo | Tsawg | Tsawg |

| Polymer / Ua npuas ncauj | Mos | Siab heev | Rough | Siab | Siab |

| Tsis-woven | Nruab nrab | Tsawg | Zoo heev | Tsawg heev | Siab |

Softer pads txiav sai dua tab sis ua tiav tsis zoo li du

Hard pads qeeb polishing thiab ntau dua burnishing

Cov txheej txheem ntau kauj ruam zoo tagnrho siv cov ntaub ntawv nyuaj kawg

Slurry Optimization

Ntsuas cov ntsiab lus abrasive / chemistry / pH / ntws tus nqi tseem ceeb

Tailor slurry formulations rau daim ntawv thov thiab ntaub qhwv

Txuas ntxiv mus sim thiab txhim kho peb cov slurries kom tau txais txiaj ntsig zoo

Tom qab Polishing Analysis

Kev ntsuas thiab tshuaj xyuas tom qab polish wafer zoo yog qhov tseem ceeb los xyuas kom meej cov ntsiab lus tau ua tiav thiab txheeb xyuas cov txheej txheem txhim kho. Cov kev ntsuam xyuas tseem ceeb muaj xws li:

Nto Roughness

Ntsuas Ra, RMS, PSD, thiab HF cov ntaub ntawv

Saib xyuas qhov ntev wavelength daim duab / flatness

Txheeb xyuas qhov khawb, qhov, qhov me me, ntxiv polishing xav tau

Zaj duab xis Thickness

Paub meej tias tshem tawm cov txheej txheej thickness (s)

Xyuas cov thickness uniformity thoob wafer nto

Haze Levels

Ntsuas haze% thiab faib

Xyuas kom meej qhov seem ntawm qhov seem puas tsawg kawg ib daim ntawv thov specs

Kev tshuaj xyuas tsis raug

Siv brightfield, darkfield, thiab lwm yam los qhia qhov seem seem

Sib piv ua ntej thiab tom qab polish defect qib / hom

Cov ntaub ntawv tawm tswv yim los kho cov ncoo, slurry, tsis

Peb cov cuab yeej ntsuas ntsuas kev sib xyaw ua ke muab kev txheeb xyuas dav dav rau kev tswj cov txheej txheem zoo.

Nto tiav

Ra<1 angstrom ua tau

RMS<2 angstroms ib txwm specification

Txo microroughness los ntawm kev ua kom zoo dua

Tag nrho Thickness Variation (TTV)

TTV <1 um hla wafer txoj kab uas hla nkag tau yooj yim

TIR <3 arc-sec tshaj qhov loj optics ua tau

Sub-nanometer thickness uniformity qhia

Defect Densities

Zero nano-scratches los ntawm ncoo txias, pub optimization

< 5 defects/cm^2 over large areas

Particle detection thiab minimization mus rau<0.1 um

Hu rau peb pab neeg ua haujlwm engineering los tshuaj xyuas koj cov kev xav tau thiab peb yuav ua kom tiav cov txheej txheem polishing kom txaus siab txawm tias cov lus qhia nruj tshaj plaws.