Wafer thinning yog cov kauj ruam tseem ceeb hauv semiconductor kev tsim khoom, thiab nws lub hom phiaj tseem ceeb yog kom tau raws li cov kev xav tau ntawm chip kev ua tau zoo, ntim, cua sov dissipation, thiab lwm yam.

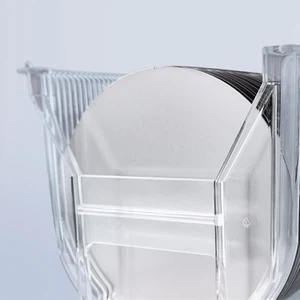

Cov txheej txheem

Thickness ntawm silicon wafer

Qhov zoo tom qab wafer thinning

Muaj kev nyab xeeb txheej txheem

WAFER BASNING thev naus laus zis

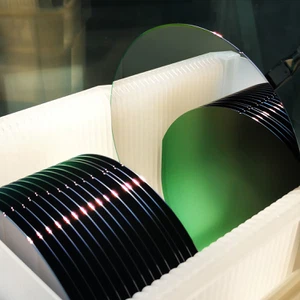

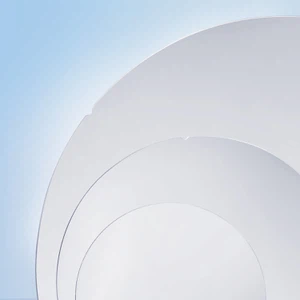

1. Silicon Wafer Thickness

Nyob rau hauv pem hauv ntej-kawg cov txheej txheem ntawm semiconductor kev tsim khoom, lub wafer yuav tsum tau ua kom tau raws li cov kev xav tau ntawm cov kev xav tau ntawm cov kev xav tau ntawm cov kev xav tau ntawm cov khoom siv ntawm cov khoom siv ntawm cov khoom siv.

150 hli ({6- nti) wafer

Cov qauv tuab: Txog 675 microns

Ntau yam: Feem ntau ntawm 650 microns thiab 700 microns

200mm ({8- nti) wafer

Cov qauv tuab: Txog 725 microns

Ntau yam: Feem ntau ntawm 700 microns thiab 750 microns

300mm ({12- nti) wafer

Txheem tuab: Txog 775 microns

Ntau yam: Feem ntau ntawm 750 microns thiab 800 microns

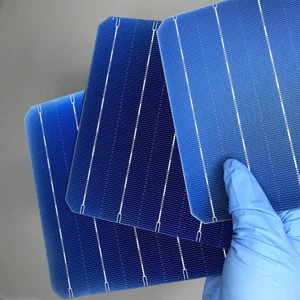

2. Qhov zoo ntawm wafer thinning

Nyob rau hauv theem ntim, kom tau raws li cov cai ntawm cov txheej txheem ntim khoom, cov wafer feem ntau yuav tsum tau thinned kom txog li 100 ~ 200 microns. Qhov no yog vim tias wined wafer tuaj yeem nqa cov txiaj ntsig hauv qab no:

Txo lub pob ntim: thinner wafers pab kom ua tiav miniaturization ntawm nti ntim

Txhim kho cov dej sov ua tau zoo: nyias wafers yog ntau dua rau cov kev tshem tawm kub

Txo cov kev ntxhov siab sab hauv

Txhim kho hluav taws xob kev ua tau: Cov wafers nyias tuaj yeem ua rau lub nraub qaum kub plating cov pob zeb hauv av, yog li ua tau zoo tshaj plaws

Txhim kho cov dicing tawm los: thinned wafers tuaj yeem txo cov khoom ntim khoom thaum lub pob dicing thiab zam kev tsis xws luag xws li ntug kev vau thiab kaum vau

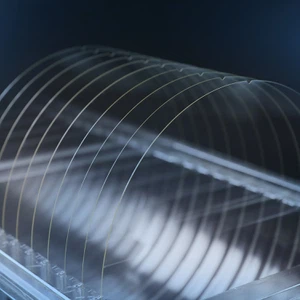

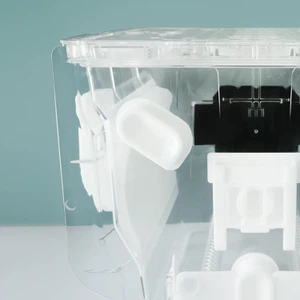

3. Way Techninning cov txheej txheem

Txhawm rau kom ua tiav wefer thinning, tshuab sib tsoo, tshuaj kho tshuab polishing (CMP) thiab lwm cov txheej txheem feem ntau yog siv.

Cov txheej txheem tshwj xeeb ntawm kev npaj ua thinning suav nrog kev npaj ua ntej, xws li kev sib tsoo ntxhib, kev ntsuas zoo, kev tshuaj xyuas zoo, thiab lwm yam).

Hauv cov thev naus laus zis ntau xws li 2.5D thiab 3D ntim, qhov xav tau nti thickness kuj tseem yuav muaj tsawg li 30 microns

4. Way Teaming Technology

1. Mechanical sib tsoo txoj kev

Txhua yam kev sib tsoo yog ib qho ntawm feem ntau siv wafer tinning txoj kev, uas tshem tawm cov khoom ntau ntawm sab nraum cov wafer los ntawm kev sib txhuam ntawm lub cev. Hom no feem ntau muab faib ua ob theem: sib tsoo ntxhib thiab sib tsoo zoo:

Kev sib tsoo ntxhib: siv pob zeb diamond lossis cov txhab nyiaj sib tsoo sib tsoo log kom tshem tawm cov khoom siv loj ntawm cov khoom siv ceev

Kev sib tsoo kom zoo: Siv cov khoom sib tsoo zoo thiab qis dua kev sib tsoo nrawm mus rau sab nraud kom zoo nkauj thiab txo cov wafer. Qhov zoo ntawm cov neeg kho tshuab sib tsoo yog qhov ua tau zoo thiab nrawm, uas haum rau huab txheej hnyav, tab sis yuav ua kom pom kev ntxhov siab thiab kev puas tsuaj saum npoo.

2. Txuj Siv Neeg Kho Tshuab Polishing (CMP)

CMP sib xyaw cov txiaj ntsig ob zaug ntawm cov tshuaj etching thiab cov neeg kho tshuab sib tsoo. Los ntawm cov nyhuv synergistic ntawm cov tshuaj lom slurry thiab polishing ncoo, nws tshem tawm morphology tsis xwm yeem thiab ua tiav cov phiaj xwm siab. CMP tuaj yeem muab cov kev tswj siab ntau dua thiab qhov zoo rau kev sib xyaw Circuit Court kev tsim nrog cov kev xav tau tsis tshua muaj.

3. Ntub etching

Ntub etching siv cov tshuaj ua kua lossis etchants rau xaiv cov khoom siv tshwj xeeb ntawm cov wafer los ntawm cov tshuaj lom neeg. Nws tau muab faib ua isotropic etching thiab anisotropic etching. Qhov zoo ntawm ntub dej etching yog cov kev xaiv siab thiab kev tswj kom zoo, uas tuaj yeem ua tiav nano-theem ua raug rau ntawm wafer saum npoo.

4. Qhuav etching

Qhuav etching siv ntshav lossis ion kab teeb kom tshem tawm cov ntaub ntawv, thiab muaj cov yam ntxwv ntawm qhov siab thiab qhov kev xaiv siab. Nws yog qhov tsim nyog rau wafer thinning uas yuav tsum muaj qhov tseeb thiab cov txheej txheem nyuaj.

5. Laser Theb

Laser rho tawm cov thev naus laus zis siv lub zog siab ntawm cov nqaj laser kom tshem tawm cov ntaub ntawv los ntawm thermal lossis photoschemical nkaus. Txoj kev no tuaj yeem ua tiav cov thinning hauv zos thiab haum rau kev ua kom zoo ntawm thaj chaw tshwj xeeb.